Pallet assignment

In addition to our CAD program, IDAT also offers production planning programs. These programs round out the range of products we offer, allowing you to map end-to-end, integrated planning from the point where the data is received from the customer to the production of the precast unit all using the IDAT software. These programs work with the machine data generated by the CAD program and are therefore fully compatible with modern production technology and central computer systems. AutoCAD is not required to run these programs. This can be done independently of CAD on a separate PC.

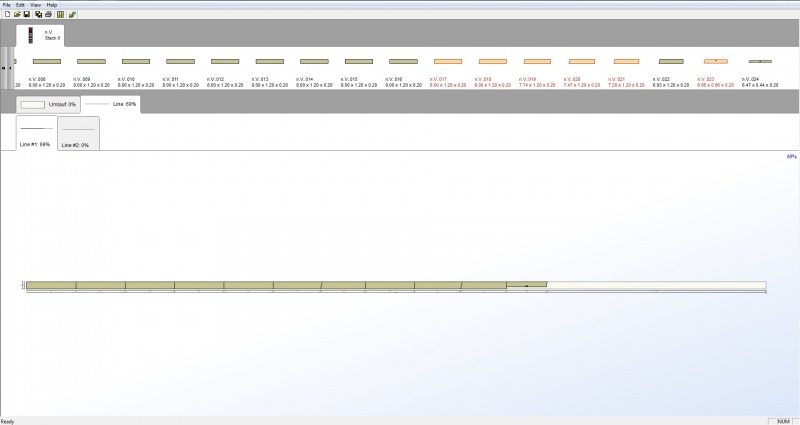

The Palletizer program is responsible for pallet or lane allocation during production. Palletizer works directly with machine data from the CAD or stacking program.

The following settings are entered in the program configuration:

- Pallet and lane dimensions

- Tray widths on the edge and at the center of the pallet

- Direction of assignment

Once the program has been launched, all prefabricated units currently queued for production are loaded into the program and displayed by stack. Naturally, several orders can be processed at the same time in the palletization program. The user can either position the prefabricated units manually onto the pallet or lane, or run fully automatic allocation. The stacking order is followed here.

The program can also process double walls. The special feature here is that two prefabricated units must be allocated simultaneously per wall (first and second skin) and monitored in terms of their position relative to each other.

Production lists with a graphic representation of the position of the prefabricated units on the pallet or lane (including detailed dimensioning) can be generated as an output. The machine data for each pallet/lane is also generated for the central computer.